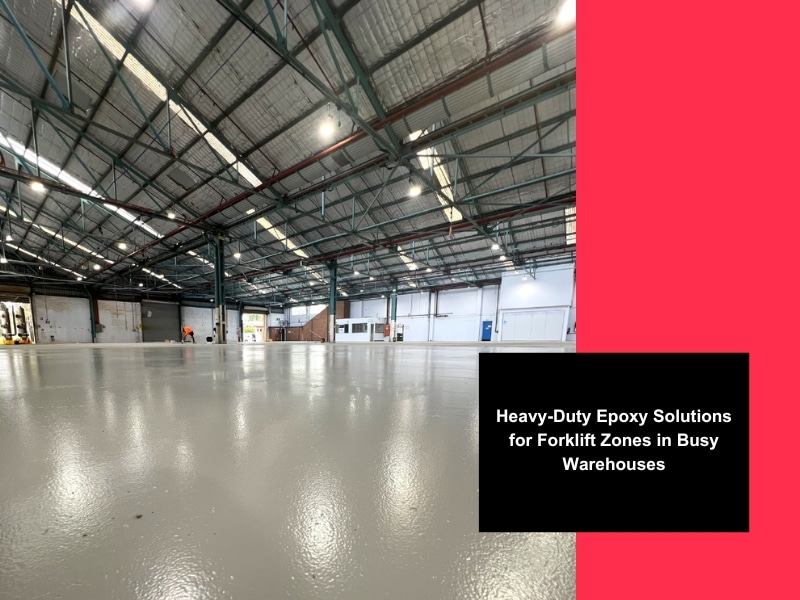

In busy warehouses, forklift zones experience constant traffic, heavy loads, and intense wear and tear. To withstand these conditions, it’s essential to have flooring that can endure the pressure and still perform reliably. That’s where heavy-duty epoxy flooring comes in. Known for its durability, strength, and safety features, heavy-duty epoxy flooring is the go-to solution for forklift zones in warehouses. This article explores why it’s such a popular choice and how it can benefit your warehouse operations.

Why is heavy-duty epoxy flooring ideal for forklift zones?

Heavy-duty epoxy flooring provides a robust solution for forklift zones, where the flooring faces constant impact, pressure, and abrasion. Here’s why it’s an ideal option:

- Exceptional durability: Epoxy flooring is resistant to damage from forklifts, heavy machinery, and pallets. Its hard-wearing surface can endure continuous traffic without cracking, chipping, or breaking down.

- Chemical resistance: Forklift zones often encounter spills from oils, fuels, and chemicals. Epoxy flooring is non-porous, making it highly resistant to such substances. It prevents damage from chemicals commonly used in warehouses, protecting both the floor and the inventory.

- High load-bearing capacity: Epoxy coatings can withstand the heavy loads that forklifts carry. The material is engineered to handle significant pressure and impact without compromising its structural integrity.

- Enhanced safety: Epoxy coatings provide a slip-resistant surface, which is crucial in areas where forklifts and workers are in constant motion. This reduces the risk of accidents and falls, contributing to a safer work environment.

With its combination of strength, resistance, and safety features, heavy-duty epoxy flooring is a smart long-term investment for any facility that relies on forklifts and heavy equipment.

What are the ideal flooring solutions for forklift zones?

For forklift zones in busy warehouses, choosing the right flooring system is crucial to ensuring both durability and safety. An ideal epoxy flooring system for such high-traffic areas includes:

- Base coat: A durable epoxy base coat, such as Koala Grey, or a custom colour tailored to your warehouse’s aesthetic and functional needs. This base provides a strong foundation that can withstand the constant impact of forklifts and heavy machinery.

- Top coat: A high-performance top coat, such as Alka 110, which is designed to offer added slip resistance, ensuring safe movement in forklift zones. This layer helps provide further protection against wear and tear, making the flooring suitable for constant activity.

- Additives: To further enhance the safety and functionality of the flooring, slip-resistant flakes can be incorporated into the epoxy. Additionally, the application of clear line markings can help define specific traffic zones, improving organisation and helping workers navigate safely.

This tailored system not only ensures a long-lasting surface but also enhances safety and efficiency within forklift zones. By incorporating these customisable options, you create a flooring solution that meets both the physical demands and safety requirements of your warehouse.

How does heavy-duty epoxy flooring improve warehouse safety?

Safety is a critical concern in any warehouse, especially in forklift zones. Heavy-duty epoxy flooring plays a vital role in reducing workplace accidents and enhancing safety. Here’s how:

- Slip resistance: By incorporating anti-slip agents into their formulation, epoxy coatings can minimise the likelihood of slips and falls, even where moisture or spills are common. Additionally, following the best practices for maintaining slip-resistant industrial floors—like regular cleaning, inspections, and timely touch-ups—helps ensure ongoing safety.

- Clear markings: Epoxy flooring can be easily marked with safety lines, guiding forklift drivers and workers through designated zones. This makes navigation safer and helps keep traffic organised.

- Improved visibility: Epoxy floors are often available in bright colours, which improve lighting and visibility, especially in low-light areas. This helps operators spot potential hazards before they become problems.

- Impact resistance: Forklifts and heavy equipment can cause damage to softer floors. Epoxy flooring provides a protective layer that resists impact, reducing the risk of damage and increasing the lifespan of the flooring.

What are the cost benefits of using heavy-duty epoxy flooring in forklift zones?

While the initial installation of heavy-duty epoxy flooring can involve some upfront costs, the long-term savings and benefits far outweigh these expenses. Here’s how:

Cost Comparison of Epoxy Flooring vs. Traditional Flooring

Feature | Epoxy Flooring | Traditional Flooring |

Initial Cost | Moderate | Low to Moderate |

Durability | High | Low |

Maintenance Costs | Low | High |

Lifespan | 10+ years | 5-7 years |

Slip Resistance | High | Varies |

Chemical Resistance | High | Low to Moderate |

Overall, the upfront investment in heavy‑duty epoxy flooring quickly pays dividends. Its long lifespan, low maintenance needs, and superior resistance to wear, chemicals, and slips mean you spend less on repairs, replacements, and downtime.

How does heavy-duty epoxy flooring contribute to warehouse efficiency?

Efficiency is key in a busy warehouse, and the right flooring can make a significant difference. Understanding what makes epoxy flooring durable in warehouses plays a crucial role in its ability to improve warehouse operations. Here’s how heavy-duty epoxy flooring enhances efficiency:

- Smooth surface: The seamless nature of epoxy flooring ensures a smooth surface for forklifts to glide across, reducing friction and wear on both the equipment and the flooring. This leads to faster and more efficient operations.

- Easy maintenance: Epoxy floors are resistant to dirt and stains, so maintaining a clean environment is much easier. This helps create a more organised and productive work environment, as workers can focus on tasks without worrying about floor upkeep.

- Customisation: Epoxy flooring can be tailored to suit specific needs, such as colour-coding areas for different forklift types or operations. This streamlines processes and boosts operational efficiency.

By combining durability, low maintenance, and customisation, heavy-duty epoxy flooring not only supports the daily demands of a warehouse but also helps create a safer, more efficient, and better-organised workspace.

What are the installation and maintenance considerations for epoxy flooring in forklift zones?

While epoxy flooring offers numerous benefits, it’s important to consider the installation and maintenance aspects to maximise its performance. Here’s what you need to know:

- Installation Time: Installing warehouse epoxy flooring in high-traffic zones requires preparation, including cleaning and priming the existing floor. The process can take several days depending on the size of the forklift zone. It’s essential to schedule the installation when the warehouse can afford minimal downtime.

- Temperature and Humidity: Epoxy flooring is sensitive to environmental conditions, such as temperature and humidity. Installation should be done in optimal conditions to ensure proper curing and adhesion.

- Maintenance Tips:

- Consistently clean the surface to eliminate dust, grease, and buildup

- Conduct routine checks to spot any signs of damage or deterioration

- Quick repairs to maintain the integrity of the surface

- Longevity: With proper care, epoxy flooring can last up to 10 years or more. However, high-traffic areas may require resurfacing or recoating after a few years to maintain both their appearance and functionality. To ensure long-lasting performance, identifying the best epoxy coating for warehouse floors is essential. Different coatings offer varying levels of protection, so selecting the right one based on your warehouse’s specific needs is crucial.

Wrapping up

Heavy-duty epoxy flooring is more than just a tough surface—it’s a smart, long-term solution for forklift zones in busy warehouses. With its unmatched durability, low maintenance needs, and built-in safety features, it helps reduce wear, improve efficiency, and minimise operational risks.

If you’re ready to make your warehouse safer and more productive, choosing the right flooring is a great place to start. Transform your workspace into a safer, smarter environment—ask us how our forklift-friendly epoxy systems can help reduce downtime and enhance safety. Discover how Ultimate Epoxy Floors can elevate your warehouse’s performance.